Search This Blog

Industrial training post and resources only. Most useful to Manufacturing, Maintenance Electricians and Mechanics, and to Engineers.

Posts

Showing posts from June, 2010

Troubleshooting PLC SCADA systems.

- Get link

- Other Apps

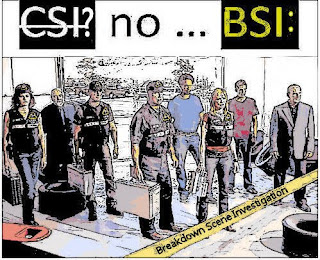

CSI? No … BSI (Breakdown Scene Investigation)

- Get link

- Other Apps