Search This Blog

Industrial training post and resources only. Most useful to Manufacturing, Maintenance Electricians and Mechanics, and to Engineers.

Posts

Showing posts from 2017

How to measure conductivity of water

- Get link

- Other Apps

The True Cost of Downtime in Manufacturing and Big Data

- Get link

- Other Apps

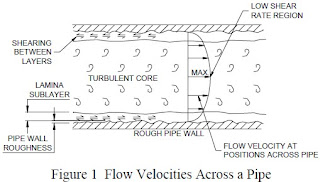

Fluid Mechanics: Industrial hydraulics training 1

- Get link

- Other Apps

Electrical circuit design software, circuit simulator - The Constructor 13

- Get link

- Other Apps