Search This Blog

Industrial training post and resources only. Most useful to Manufacturing, Maintenance Electricians and Mechanics, and to Engineers.

Posts

Showing posts from 2014

Mobile Industrial Workstation to Smartphone

- Get link

- Other Apps

Maintenance Management Training Online

- Get link

- Other Apps

Industrial Communication Protocol Comparison

- Get link

- Other Apps

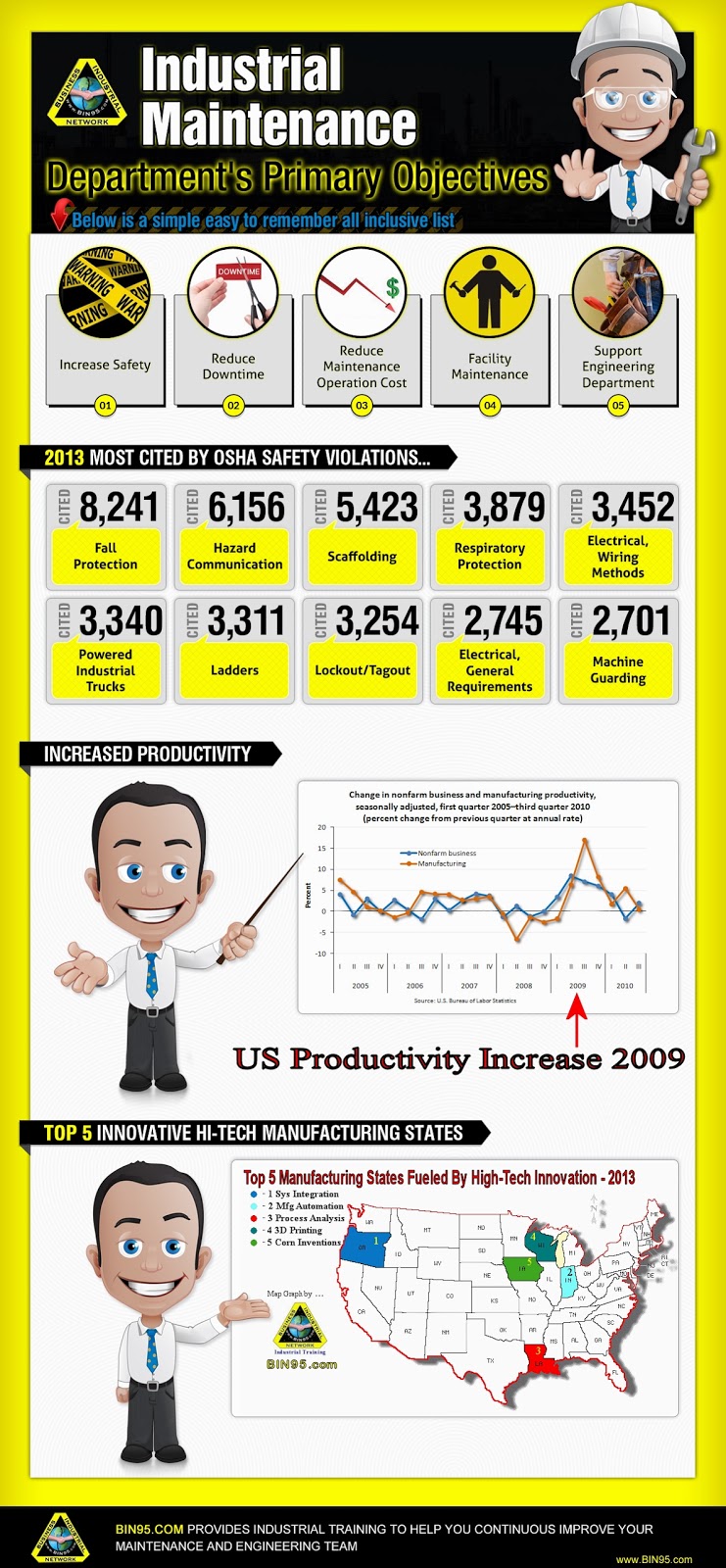

Maintenance Management Objectives

- Get link

- Other Apps