Search This Blog

Industrial training post and resources only. Most useful to Manufacturing, Maintenance Electricians and Mechanics, and to Engineers.

Posts

Showing posts from 2012

#HappyHolidays This #Christmas morning

- Get link

- Other Apps

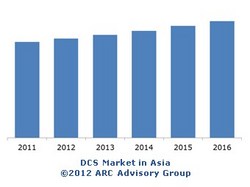

Advanced Manufacturing = Advanced Automation Control

- Get link

- Other Apps

Industrial Android App replaces VOMs

- Get link

- Other Apps

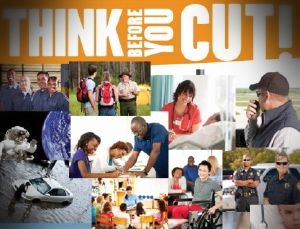

Missouri: Workforce development programs to be cut by 20%

- Get link

- Other Apps

WTC 9-11 #NeverForget911 - Also Important, Learn from 9-11

- Get link

- Other Apps

NEW - You Can Be Maintenance Hero. Free Prizes

- Get link

- Other Apps

Learning through Application for Return On Training Investment

- Get link

- Other Apps

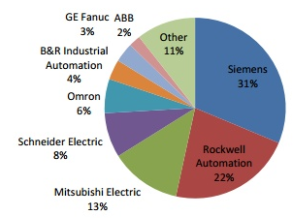

Global Market Share of PLC Brands:

- Get link

- Other Apps

Engineering Funny Connections - Maintenance Crisis NOT so funny though.

- Get link

- Other Apps

Great Educational Speakers - A YouTube Playlist

- Get link

- Other Apps

Survey: Skills Gap Hits Employee Morale and Company Revenue

- Get link

- Other Apps

Engineering Education in the 21st Century

- Get link

- Other Apps

In memory of Dr. Genichi Taguchi (January 1, 1924 - June 2, 2012)

- Get link

- Other Apps

Lean in manufacturing,what is Jidoka?

- Get link

- Other Apps

Lean TPM Autonomous Maintenance 2

- Get link

- Other Apps

Help with Maintenance Training Program Matrix

- Get link

- Other Apps

Incorporate Best Practices into Training

- Get link

- Other Apps

Best Practices for Conveyor Maintenance

- Get link

- Other Apps

7 Mistakes you don't want to hear your PLC Tech say.

- Get link

- Other Apps

Solutions to the Skills Training Shortage

- Get link

- Other Apps