Search This Blog

Industrial training post and resources only. Most useful to Manufacturing, Maintenance Electricians and Mechanics, and to Engineers.

Posts

Showing posts from 2011

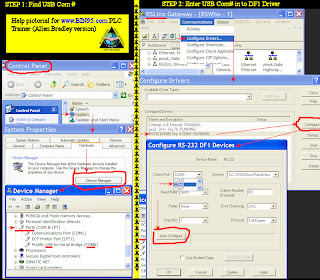

Connecting to PLC and other Industrial Equipment via USB

- Get link

- Other Apps

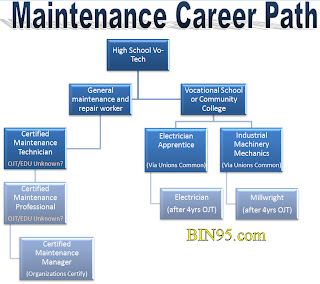

Beef up that Resume with PLC Training

- Get link

- Other Apps

Are you wasting your time and money on a college degree for which there are no jobs?

- Get link

- Other Apps

Thinking Out Of The Box: "No Labor" Manufacturing Goal

- Get link

- Other Apps

USA - Maintenance Managers Wanted

- Get link

- Other Apps

Air Compressor Operation and Care

- Get link

- Other Apps

Oil and Gas Refinery Debottlenecking, clean exchanger tubes.

- Get link

- Other Apps

Problem Solving Skills Training Video

- Get link

- Other Apps

11/11/11 discount of 11% on TwitPic

- Get link

- Other Apps

Maintenance Troubleshooting Skills Training

- Get link

- Other Apps

Free On-Line 5S Lean Manufacturing Assessment

- Get link

- Other Apps

Industrial Jobs Require Technical Clarity

- Get link

- Other Apps

Frustrated Maintenance Technicians and Maintenance Managers

- Get link

- Other Apps

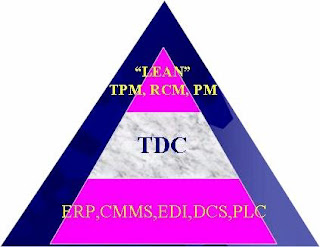

Craft Maintenance Training: Blueprint for Success

- Get link

- Other Apps

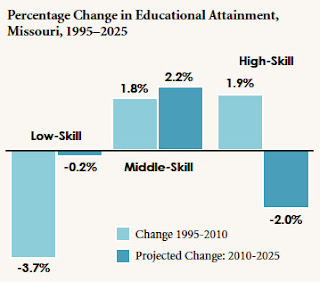

Middle-Skill Jobs in the American South's Economy

- Get link

- Other Apps

Can our educational system fill the skills gap?

- Get link

- Other Apps

Cost Justifying Industrial Electrical Training

- Get link

- Other Apps

100s of Free Industrial Training Videos

- Get link

- Other Apps

Training Half Life (worker retraining)

- Get link

- Other Apps

What has happened to the skilled labor force?

- Get link

- Other Apps

I want to be an Engineer, so freakin' bad...

- Get link

- Other Apps

Industrial Training - Education - Facebook Fan Page

- Get link

- Other Apps

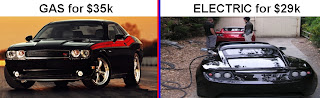

Electric Automobile Manufacturing Industry

- Get link

- Other Apps

Lights Out Factory - Robots Replacing Workers

- Get link

- Other Apps

New Free Industrial Knowledge App (AnDroid App version)

- Get link

- Other Apps

Industrial Training - Programmable Logic Controllers (PLC)

- Get link

- Other Apps

Roadmap for Education Reform for Manufacturing

- Get link

- Other Apps

Investigating Power Outages At A ‘Mud’ Plant

- Get link

- Other Apps

Do your know FMECA/RCM/RCA results point to Training Needs / Knowledge gaps?

- Get link

- Other Apps

Industrial Networking Solutions Security - PLC, SCADA

- Get link

- Other Apps

Free Engineering Training Software for my Friends

- Get link

- Other Apps

Manufacturing Ohio: MACHINING 102

- Get link

- Other Apps

Automation in Green Manufacturing

- Get link

- Other Apps

Industrial Pumps: Positive Displacement Pumps Training

- Get link

- Other Apps

Electrical Inspection Checklists and Resources

- Get link

- Other Apps

How Often Should Electrical PM be done?

- Get link

- Other Apps