What is Autonomous Maintenance?

These Autonomous Maintenance Steps answer best...

Autonomous Maintenance (AM) is the first step in Total Productive Maintenance (TPM) methodology which is a part of the LEAN manufacturing philosophy.

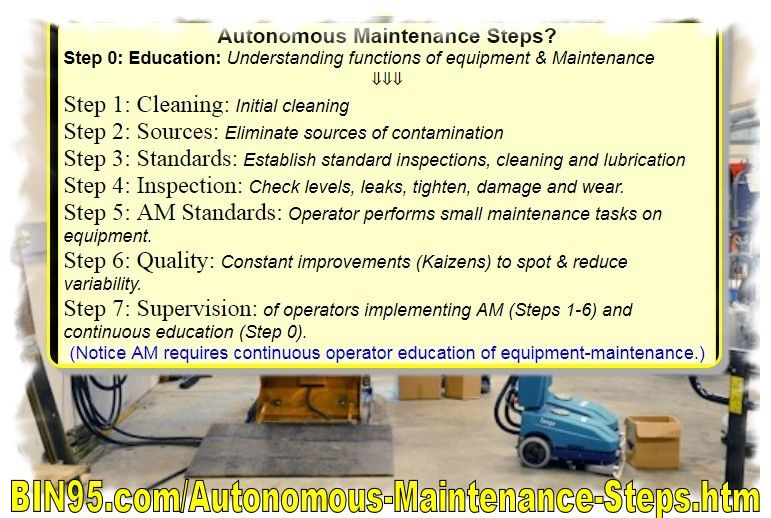

Autonomous Maintenance Steps:

Step 0 Is the lessor known and practiced autonomous maintenance step, has the goal of educating machine operators on the basic knowledge of machine components functions and maintenance best practices.Step 1 of autonomous maintenance is cleaning and inspection. Its sole purpose is to remove grime and dirt from the machine in order to identify any problem associated with the machine. In so doing, the operation of the machine is stopped, all fluids drained and all machine covers removed in order to reveal all parts to be cleaned and inspected.

Step 2 sets out to remove causes of contamination in order to improve access. In this stage, the source of the dirt is of the primary concern operators seek how to minimize the sources of contamination.

Step 3 is about the cleaning and lubrication standards. These standards define what the operators should inspect, clean, lubricate and tighten, how it should be done, after what period and such like.

Step 4: The operators should be trained to gain enough expertise on the function of the machine parts and solution finding skills. They are undergo an in depth training to familiarize themselves of the functionality as well as obligations.

Step 5: Conduction of autonomous inspection using the skills and knowledge gained from the first four steps. Tasks are bench-marked with that of other maintenance departments so that scheduling avoids overlapping effort.

Step 6: Implementation of visual maintenance management to make the workplace as visible as possible. Using a Kamishabi board is important as it points out when and what has been completed.

Step 7: The process is based on the principle of continuous improvement. Records of activities done are subjected to auditing regularly. Achievements and failures are iterated to future designs to improve and make maintenance easier.

With AM Step 0 being the key one to insure greater success with all the other steps, you should learn more. Here are some additional resources to help you.

LEAN | TPM | Autonomous Maintenance Steps | Step 0: Education

Operator Autonomous maintenance Training (OATs)

AM 2 In-house Training Program

Do your part to make the world a better place, please share these resources with others. Everyone could use more success and profits. 👷

Don (Follow me on Industrial Skills Training Blog and on Twitter @IndTraining .) Be sure to add me to your Google+ circles to stay on top!

Comments