Allen Bradley VFD Training

Allen Bradley VFD Training, and Sizing VFD for Motor.: Allen Bradley VFD Training key points samples. Samples: Freak drive operating principles, sizing VFD for motor, variable frequency operating temperatures.

Excerpts ...

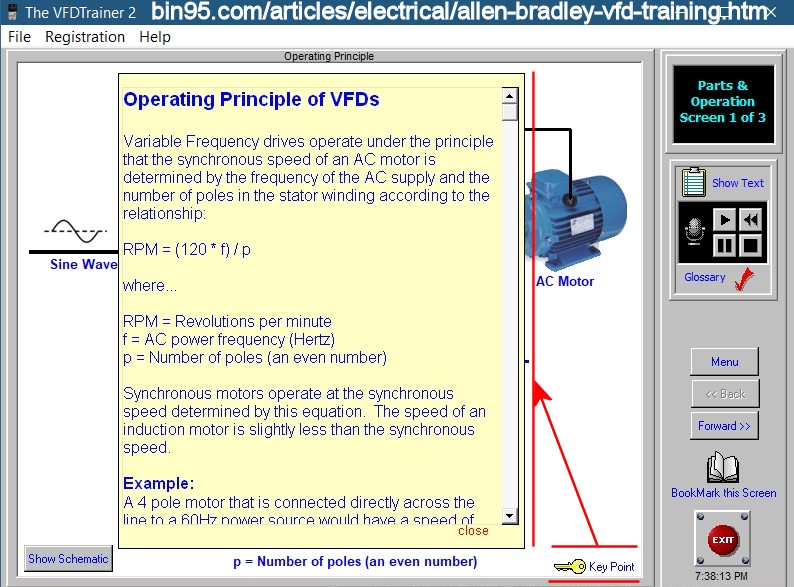

VFD Drive Working Principles:

Variable Frequency drives operate under the principle that the synchronous speed of an AC motor is determined by the frequency of the AC supply and the number of poles in the stator winding according to the relationship:

RPM = (120 * f) / p

where...

RPM = Revolutions per minute

f = AC power frequency (Hertz)

p = Number of poles (an even number)

Synchronous motors operate at the synchronous speed determined by this equation. The speed of an induction motor is slightly less than the synchronous speed.

Example: in the full article at https://bin95.com/articles/electrical/allen-bradley-vfd-training.htm

Sizing VFD For Motor:

How do you size a VFD drive for an application and feel confident it's going to work?

You must understand the requirements of the load. You should also understand the difference between horsepower and torque. Both torque and horsepower must be carefully examined.

Torque:

Torque is an applied force that tends to produce rotation and is measured in lb-ft or lb-in. All loads have a torque requirement that must be met by the motor. The purpose of the motor is to develop enough torque to meet the requirements of the load.

The torque can be thought of as "OOUMPH". The motor must develop enough "OOUMPH" to get the load moving and keep it moving under all the conditions that may apply.

Horsepower:

Horsepower (hp) is the time rate at which work is being done. One hp is the force required to lift 33,000 lbs. 1 ft in 1 min.

Some basic equations will help you understand the relationship between hp, torque, and speed.

hp = (Torque x Speed)/5250 (eq. 1)

Torque = (hp x 5250)/Speed (eq. 2)

For example, a 1-hp motor operating at 1800 rpm will develop 2.92 lb-ft of torque.

Continued in full article...

VFD Applications to watch out for:

If you answer any of the following questions with YES, be extra careful in your VFD selection and setup parameters of the VFD.

Will the VFD drive operate more than one motor?

The total peak currents of all motor loads under the worst operating conditions must be calculated. The VFD must be sized based on this maximum current requirement. Additionally, individual motor protection must be provided here for each motor.

Will the load be spinning or coasting when the VFD drive is started?

This is very often the case with fan applications. When a VFD is first started, it begins to operate at a low frequency and voltage and gradually ramps up to a preset speed. If the load is already in motion, it will be out of sync with the VFD. The VFD will attempt to pull the motor down to the lower frequency, which may require high current levels, usually causing an overcurrent trip. Because of this, VFD manufacturers offer drives with ...

Continued in the article at https://bin95.com/articles/electrical/allen-bradley-vfd-training.htm

The above should have given you enough to decide to read the full article or not, and the article gives you more insight into the Allen Bradley VFD certificate course. I hope you like and share with others.

Comments